China Sourcing Trip for the Canton Fair & Nearby Cities

For many global buyers, the Canton Fair is the starting point of a sourcing trip to China. It offers unmatched exposure to suppliers across industries, but the fair itself is only part of the large China market.

To attend the exhibition, the real challenge begins with what comes before and after: Limited time, overwhelming information, and unclear supplier capabilities at the fair. Many Importers usually leave China only with samples and quotations. They can't make confident sourcing decisions.

While a planned China sourcing trip allows you to go beyond the trade fair. By combining the fulfilling Canton Fair tour and nearby sourcing cities, you can verify suppliers, compare real production capabilities, and negotiate from a stronger position.

This comprehensive guide is designed to make your journey more efficient. Follow this blog, explore a complete visit, not just a trade show visit.

The Canton Fair, officially known as the China Import and Export Fair. It is the barometer of China's foreign trade, one of the largest and most comprehensive trade fairs in the world. Since 1957, it has been held in Guangzhou 138 times, bringing thousands of trustworthy Chinese manufacturers to global importers.

Its scale and diversity make it unmatched in the trade fair scene. Accourding Global Times, there are 35,000 exhibitors at the 133rd Canton Fair. Split into three phases, the fair covers a vast array of industries. From electronics to textiles, each phase focuses on specific categories.

For global buyers, the Canton Fair remains the stop when planning a China sourcing trip. This exhibition offers an excellent chance to clear China's manufacturing landscape. The core value lies in:

Rapid supplier comparison across the same product categories.

Direct communication with manufacturers and export teams.

Clear market pricing signals based on real-time quotations.

Early risk screening through on-site interaction and sample evaluation.

However, the Canton Fair is best used as a starting point rather than a final decision. Don't forget visit nearby sourcing cities to get the best terms.

Both the Canton Fair and online B2B sourcing platforms(like Alibaba) play important roles in modern China sourcing. The key difference is in how buyers evaluate suppliers, products, and risk at different stages of the sourcing process. Based on our China sourcing experience, we have made a short table to help you understand them.

|

Criteria |

Canton Fair |

Online Sourcing |

|

Product Variety |

Broad, export-oriented product categories with new launches |

Extremely wide range, including niche and low-MOQ products |

|

Pricing Transparency |

Indicative pricing, useful for market benchmarking |

Visible pricing, but often inconsistent or non-final |

|

Product Quality Assessment |

Physical samples and face-to-face discussion |

Photos, videos, and reviews with limited verification |

|

Convenience & Speed |

Time- and travel-intensive, but highly efficient on-site |

Highly convenient and fast to start remotely |

|

Supplier Reliability |

Easier to judge communication quality and professionalism |

Requires strong verification and due diligence |

|

Best Suited For |

Buyers with some experience in wholesale from China |

New buyers focused on quick sourcing |

In practice, we found experienced buyers often combine both methods. They browsed on Alibaba in advance and compiled a list of potential suppliers. Then attend the Canton Fair to conduct on-site sample inspection and communication. Finally, they visit the factory for inspection and negotiations.

Each phase lasts only five days, but features nearly 20 exhibition areas. Canton Fair is brief, intense, and packed with information. Without a comprehensive and structured itinerary, buyers might leave with contacts but lack a clear buying plan.

A pre-program helps maximize your time to make specific sourcing results. The most effective sourcing trips follow a three-stage structure: preparation before the fair, structured data collection during the fair, and verification after the fair.

Effective sourcing at the Canton Fair begins long before arrival. Pre-fair preparation determines whether on-site visits are focused and actionable, or scattered and inefficient. This work generally involves product definition, supplier screening, and route planning.

First, clarify what products align with your business. Then you can choose a suitable exhibition period to participate in. For example, source hardware and tools in Phase 1, home decor and furniture in Phase 2, and electric toys or hobby products in Phase 3.

Moreover, buyers should clearly define their sourcing products to ensure focused and productive visiting. This includes:

Technical specifications: such as material type, dimensions, weight, color variants, or certifications (e.g., CE, RoHS, FDA).

Quality standards: tolerance limits, finishing, durability tests, or packaging requirements.

Compliance requirements: relevant safety, labeling, or environmental standards for your target market.

Acceptable MOQ and staged pricing: for example, 500–1,000 units at one price, 1,000–5,000 units at a discounted rate.

Considering the Canton Fair scale, finding every supplier in person is not an efficient approach. So importers can pre-screen suppliers in advance by using the official Canton Fair exhibitor lists or online sourcing platforms such as Alibaba, Global Sources, or other verified directories. This allows identification of manufacturers that match your product categories, certifications, MOQ requirements, and production capabilities quickly.

Scheduling meetings ahead of time ensures dedicated discussion slots with qualified suppliers, reducing the risk of missing key opportunities during peak fair hours.

A planned route between halls helps maximize time on-site and reduces unnecessary backtracking. Grouping supplier visits by product category improves efficiency.

Writing clear product summaries and organized questions helps improve communication. It makes discussing specifications, customization options, and pricing details easier. And download necessary translation apps in advance to avoid unclear communication.

Effective sourcing during the Canton Fair requires structured data collection and on-site evaluation. You should focus on their product metrics, communication skills and sample quality. These informations support post-fair evaluation and decision-making.

When attending the Canton Fair, buyers are advised to record supplier quotations using consistent criteria, including details such as the supplier's name, the product, the price, minimum order quantities (MOQs), delivery times, and other relevant information. This step enables accurate comparison and avoids decisions based on incomplete or inconsistent information.

Below is a template commonly used by EJET for structured on-site data collection:

|

Supplier Name |

Product |

Price per Unit |

MOQ |

Lead Time |

Certifications |

Notes / Observations |

|

Supplier A |

Plush Toy A |

$2.50 |

500 |

30 days |

CE, RoHS |

Sample quality acceptable, packaging OK |

|

Supplier B |

Plush Toy B |

$2.40 |

1000 |

25 days |

CE |

Communication very responsive |

|

Supplier C |

Plush Toy C |

$2.60 |

500 |

35 days |

None |

Requires customization, clarify MOQ |

How to Use:

Fill out the table for each supplier and product during the fair.

Include all relevant metrics: price, MOQ, lead time, certifications, and short notes on quality or responsiveness.

Compare suppliers side by side after the fair to shortlist candidates for factory visits or negotiations.

On-site interaction provides insight into how suppliers communicate under real-time conditions. Buyers should assess clarity, responsiveness, and problem-solving ability during discussions. Because these factors often reflect future cooperation quality.

Physical samples help buyers check materials, work quality, and finishing details. It is important to look for consistency and make sure the sample matches the production standards. Don't assume that samples shown in exhibits reflect the quality of mass production.

When inspecting samples, buyers should consider:

Material and texture: Verify that the material matches specifications (e.g., type of plastic, fabric, metal grade) and feels consistent across units.

Construction and workmanship: Check seams, joints, soldering, or assembly quality; uneven finishes or weak joints may indicate production risks.

Dimensions and weight: Measure key dimensions and weight to ensure they meet your requirements and tolerances.

Color consistency: Compare color across multiple pieces; inconsistent coloring often signals poor quality control.

Functionality: If the product has moving parts, electronics, or mechanical components, test them for reliability and smooth operation.

Packaging quality: Assess whether packaging protects the product during transit and matches your branding or compliance needs.

Sample vs. mass production alignment: Ask the supplier how the sample represents bulk production; check for any deviations in materials, finishes, or tolerances.

Document all observations in a standardized template for comparison across suppliers. This structured approach reduces the risk of quality surprises when placing bulk orders.

Follow-up is where initial impressions are validated, and sourcing risks are reduced. Factory visits, sample verification, and structured negotiations transform fair contacts into reliable supplier relationships.

This is the most important step after you attend every exhibition. Factory visits or third-party audits help confirm production capacity, quality control processes, and compliance with required standards. However, when we accompanied buyers on factory inspections, we found that they were unaware of how to do it properly.

So, during the factory audition, buyers should pay attention to several key aspects that reveal suppliers' productioncapacity:

Production flow: Observe the organization of the production line, workflow efficiency, and whether processes are standardized.

Quality checkpoints: Check for inspection points, testing stations, or quality control procedures at each production stage.

Workforce stability and skill level: Assess employee experience, turnover rate, and training programs.

Equipment and machinery condition: Evaluate whether the machinery is modern, well-maintained, and suitable for the product being manufactured.

Raw material storage and handling: Examine how materials are stored and handled.

Safety and compliance standards: Look for adherence to local safety regulations, protective equipment, and fire prevention measures.

To make these observations actionable, EJET recommends using a standardized Factory Visit Evaluation Table:

|

Observation Point |

Evaluation Criteria |

|

Production flow |

Excellent: ≥80% processes standard Medium: 60–79% processes standard High Risk: <60% processes standard |

|

Quality checkpoints |

Excellent: QC every 50–100 units Medium: QC every 200–500 units High Risk: QC only at final stage or >500 units |

|

Workforce stability & skill |

Excellent: ≥3 yrs avg experience, turnover <5% Medium: 1–3 yrs avg experience, turnover 5–15% High Risk: <1 yr avg experience, turnover >15% |

|

Equipment & machinery |

Excellent: >80% machines <5 yrs, well-maintained Medium: 50–80% machines <5 yrs High Risk: <50% machines <5 yrs, poor maintenance |

|

Raw material storage & handling |

Excellent: all labeled and protected Medium: most labeled, minor storage issues High Risk: unlabeled or poorly stored |

|

Safety & compliance |

Excellent: full compliance, regular training Medium: partial compliance, some PPE/training missing High Risk: non-compliance, missing measures |

Evaluation criteria are based on international standards such as ISO 9001, ISO 45001, and industry best practices for factory audits.

Once buyers have confirmed supplier capabilities through factory tours and testing samples, you can negotiate with more assurance. This leads to more realistic agreements and fewer post-order disputes. Key topics to discuss include prices, minimum order quantities (MOQs), delivery schedules, payment conditions, and quality assurances.

Beyond the immediate order, consider the supplier's long-term potential: plan trial orders, establish clear communication channels, and set expectations for future collaborations. This approach ensures that initial sourcing decisions evolve into stable, reliable partnerships, reducing risks and supporting ongoing supply chain growth.

The Canton Fair is an efficient starting point for identifying potential suppliers across industries. However, due to limited exhibition space and time constraints, many suppliers present only selected samples and marketing materials. Buyers cannot get their full production capabilities.

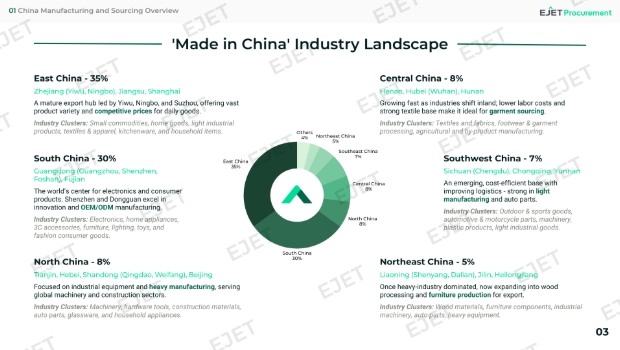

Visiting nearby sourcing cities after the exhibition allows you to verify factory operations and assess real manufacturing capacity. Then move from initial interest to informed decision-making. Here is a chart to express China's manufacturing landscape(You can contact our customer service to learn more).

Among these destinations, Shenzhen, Dongguan, Yiwu, and Chongqing stand out as key southern cities for buyers sourcing from China.

Located just a short trip from Guangzhou, Shenzhen is one of the most strategic sourcing destinations to visit after the Canton Fair. In Shenzhen, you can explore advanced manufacturing clusters and negotiate directly with tech-driven factories.

Shenzhen thrives in the electronics sector. It produces smart devices, components, and IoT solutions. Key sourcing categories include:

Consumer Electronics: Bluetooth earphones, smart watches, chargers, power banks

Smart Devices & IoT Products: smart home devices, sensors, control panels

Electronic Components: PCBs, chips, connectors, modules

Hardware & Accessories: phone cases, cables, adapters, metal and plastic housings

OEM / ODM Electronics: customized electronics for private label brands

Many factories in Shenzhen specialize in small-batch production, rapid prototyping, and frequent model updates. The city is especially attractive for fast-moving markets.

Shenzhen remains unmatched for technology-driven sourcing. Specifically, it's suitable for:

Electronics brands and private label sellers

Amazon and DTC sellers require frequent product upgrades

Buyers seeking OEM/ODM customization, not just off-the-shelf products

Startups and growth-stage companies needing fast iteration and engineering support

Travel tips:

Shenzhen is easily accessible from Guangzhou by high-speed train (≈1 hour)

Factory visits should be scheduled in advance, as many suppliers operate multiple sites

Allocate time to visit Huaqiangbei only for market insights, not factory validation

Common risks:

Some “factories” are actually trading companies with showrooms

Strong samples may rely on outsourced assembly, not in-house production

Overpromising on customization speed and certification readiness

To reduce these risks, buyers should focus on on-site verification, request production records, and confirm engineering ownership before placing orders.

Located between Guangzhou and Shenzhen, Dongguan is a manufacturing powerhouse and a natural extension of Canton Fair sourcing trips. This city allows buyers to go deeper into core manufacturing processes, cost structures, and production scalability.

Dongguan is known for its strong industrial base and mature supply chains. Here, factories excel in mass production, stable quality control, and competitive pricing. Key sourcing categories include:

Hardware & Metal Products: fasteners, hinges, brackets, stamped parts

Plastic Products & Injection Molding: consumer goods, packaging components, enclosures

Furniture & Home Products: upholstered furniture, office furniture, wooden components

Toys & Gift Items: plastic toys, promotional items, seasonal products

OEM / ODM Manufacturing: large-scale customized production for global brands

Dongguan is best suited for buyers who prioritize manufacturing depth and cost efficiency, including:

Buyers placing medium to large volume orders

Brands seeking reliable OEM partners with mature QC systems

Importers focused on cost optimization and production stability

Buyers sourcing hardware, plastic, or furniture-related products

Travel tips:

Dongguan is reachable from Guangzhou within 1–1.5 hours by car or train

Plan factory visits by industrial zone to reduce travel time

Allocate sufficient time for production line observation, not just sample rooms

Common risks:

Some factories subcontract key processes without disclosure

Quotation differences between sthe ample stage and mass production

Limited flexibility for small MOQs or frequent design changes

Buyers should verify in-house production capabilities, subcontracting scope, and cost breakdowns before confirming orders.

Located in Zhejiang Province, Yiwu is known as "The World Capital of Small Commodities", which complements the Canton Fair. This city is built around high-efficiency wholesale ecosystems for small commodities.

Yiwu suppliers often offer ready-made designs, rapid order fulfillment, and flexible MOQs, making it ideal for fast product testing. Key sourcing categories include:

Daily Consumer Goods: household items, storage products, kitchen accessories

Fashion Accessories: jewelry, bags, scarves, hair accessories

Gifts & Promotional Products: seasonal decorations, party supplies

Stationery & Office Supplies: notebooks, pens, school items

Small Home Décor Items: artificial flowers, ornaments, candles

Yiwu is particularly suitable for:

Wholesalers and distributors managing wide product ranges

Amazon, e-commerce, and dropshipping sellers are testing new SKUs

Buyers prioritizing low MOQs and fast turnover

Importers sourcing non-complex, standardized products

Travel tips:

Yiwu is accessible from Guangzhou via domestic flight in 2 hours or high-speed rail in 5 hours

Allow multiple days to navigate the Yiwu International Trade Market efficiently

Focus on supplier credibility, not just booth size or product variety

Common risks:

Many suppliers are trading companies rather than manufacturers

Quality inconsistency across batches

Limited customization or engineering capability

Buyers should request samples from multiple suppliers and validate consistency before scaling orders.

Located in Southwest China, Chongqing is emerging as a strategic inland manufacturing hub. For buyers looking beyond coastal sourcing, Chongqing offers cost advantages and growing industrial specialization.

Chongqing's manufacturing strengths are driven by government-supported industrial development. Factories here offer large-scale production with lower labor and facility costs compared to coastal regions. Key sourcing categories include:

Automotive Parts & Components: interior parts, metal components, electrical systems

Motorcycles & Accessories: engines, frames, spare parts

Machinery & Industrial Equipment: tools, mechanical assemblies

Electronics Assembly: laptops, displays, electronic sub-assemblies

OEM Industrial Manufacturing: customized industrial products

Different from Guangdong and Yiwu cities, Chongqing is best suited for:

Buyers sourcing industrial or automotive-related products

Companies prioritizing cost efficiency over proximity to ports

Long-term buyers with stable demand forecasts

Importers expanding supply chains beyond coastal China

Travel tips:

Chongqing requires domestic flights from Guangzhou

Allocate time for logistics planning due to the inland location

Factory visits should include logistics and export process reviews

Common risks:

Longer 1-week lead times due to inland transportation

Communication gaps with less export-experienced factories

Slower response for small or trial orders

Buyers should confirm export experience, logistics routes, and lead time buffers before committing to large-scale cooperation.

|

City |

Primary Products |

Key Advantages |

Best For |

|

Shenzhen |

Consumer electronics, smart devices, IoT products, electronic components, OEM/ODM electronics |

Strong R&D capability, fast prototyping, frequent model updates |

Electronics brands, Amazon & DTC sellers, buyers needing rapid iteration and customization |

|

Dongguan |

Hardware products, metal and plastic parts, furniture, toys, OEM manufacturing |

Mature supply chains, stable mass production, cost-efficient scaling |

Buyers moving from samples to mass production, cost-focused OEM sourcing |

|

Yiwu |

Small commodities, daily consumer goods, gifts, accessories, stationery |

Extremely wide product variety, low MOQs, fast sourcing turnover |

Wholesalers, e-commerce sellers testing multiple SKUs |

|

Chongqing |

Automotive parts, motorcycles, machinery, industrial equipment, electronics assembly |

Lower manufacturing costs, growing inland industrial clusters |

Industrial buyers, automotive sourcing, long-term supply chain expansion |

To work effectively with a China sourcing agent, clear communication before and during your trip is essential. Partnership starts by sharing product scope, target categories, expected MOQs, customization needs, and compliance requirements. The agent will pre-screen suppliers and prepare factory visits based on real sourcing criteria.

During the Canton Fair and post-fair city visits, align with your sourcing agent on evaluation standards. Discuss how quotes should look, what samples you expect, production capacity, and delivery times. Consistent criteria help ensure on-site decisions are comparable and actionable.

EJET's China sourcing trip guide supports buyers in Canton Fair Guide Tour, China Markets Guided Tour, and Factory Audit & Tour Coordination. The one-stop service includes pre-supplier screening, on-site negotiation assistance, multi-city factory visits, and follow-up. Our local teams help 1,500+ buyers translate fair contacts into verified suppliers and long-term sourcing partnerships.

The Canton Fair is an efficient entry point into China sourcing, but real results come from what happens beyond the exhibition halls. Careful planning, structured supplier evaluation, and post-fair factory verification are essential to turning fair discoveries into reliable supply chains.

By combining fair participation with targeted visits to nearby sourcing cities, buyers can reduce risks and improve decision accuracy. Working with experienced local partners further supports the development of stable, long-term supplier relationships.

Yes. The fair is open to overseas visitors, and a business visa is not mandatory for entry. However, visa requirements may vary by nationality. The M visa may be more convenient in some aspects.

Hotels near Pazhou (Canton Fair Complex) are the most convenient, especially during fair days. Areas such as Zhujiang New Town and Tianhe District are also popular due to good metro connections, dining options, and business facilities. Early booking is strongly recommended, as availability becomes limited during fair periods.

After the Canton Fair, many buyers travel to nearby sourcing cities based on product focus. Shenzhen is ideal for electronics and OEM/ODM products, Dongguan for mass manufacturing and hardware, Yiwu for small commodities and low-MOQ goods, and Chongqing for industrial and automotive sourcing. Visiting these cities allows buyers to verify factories and assess real production capabilities.

To maximize a China sourcing trip, buyers should define product requirements in advance, pre-screen suppliers, and schedule factory visits beyond the Canton Fair. Combining fair participation with on-site verification and structured supplier evaluation helps reduce sourcing risks. Working with a local sourcing partner like EJET can further support supplier screening, factory audits, and post-visit follow-up.

Your trusted partner for sourcing from china.